In two earlier articles about the proposed Pamlico 6 thru12 school, I quoted some statistics for the time frame of 2010 to 2022:

-

Pamlico County lost 5.5 percent of its population

-

School aged people (5 to 19) decreased 25.2 percent

-

The 65-plus population increased 31.6 percent

-

Over same 12-year period, USA population increased 7.7 percent

-

North Carolina population increased 11.7 percent

Government estimates put the number of births for the year 2023 at 53.3 births per 1,000 women. That sounds like a goodly number, but it is the LOWEST since records of that statistic have been kept in the USA! Also the 2023 number was 3 percent lower than the 2022 number, which in turn was lower than the 2021 number.

These data markers mean the student population for the Pamlico school will continue to decline in the future, even though the new school has been designed for an increased number of students – NOT FEWER! The school system is supported by federal and state funds, with appropriations made on a per student basis. As the student population declines, funding will be reduced proportionally.

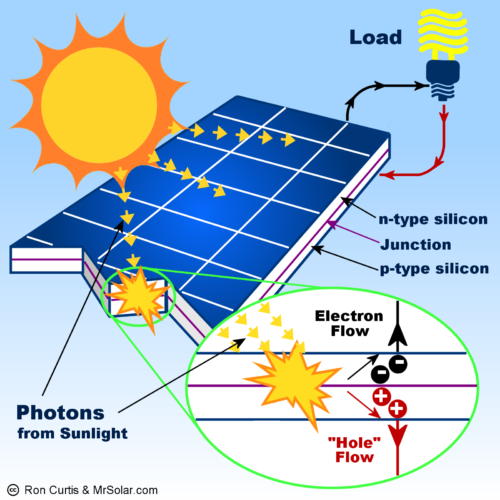

The concept of the rooftop solar voltaic array has been ‘pitched’ to the Pamlico school community with the ‘promise’ of future replacement cells being cheaper than those of today. That premise may or may not be accurate. A solar voltaic panel absorbs light from the sun and produces a DC voltage at the output of each panel. The panels are connected in parallel and series to achieve the voltage and currents required by the system. The DC power is carried from the roof into the inverter system. The inverters take in the DC power and generate AC power, which runs the school’s electrical equipment. The local power grid ‘reads’ the inverter output so that it is in phase with the local AC power from the electric utility.

THIS DOES TWO THINGS. First, it allows excess power generated by the photo voltaic system to backfeed so the solar system supplies power to the local utility electric grid, and the school system is paid for that excess power by the electric company. Second, safety! If for some reason (storms, etc.) power is lost at the school, the inverters stop producing AC power so it cannot be backfed into the electrical system to burn or electrocute the electric company linemen.

Any replacement solar panels must be placed exactly where the original panels were located, and the weight of the new panels must be comparable to that of the originals. A goodly amount of labor will be required to remove the old panels and install the new ones. Solar panel frames must be removed from the roof with heavy duty cranes.

Right now, this type of crane is available in nearby Bridgeton. Should local crane rental fail to exist in the 20 to 25 years after the school is built, beware the cost to rent cranes from distant locations. Hopefully solar panel replacement could occur at the same time the roofing needs replacement. But an EMP (ElectroMagnetic Pulse) attack – inflicted by an adversary – would screw that up when the panels suddenly die.

NREL (National Renewable Energy Labs, Golden, CO) has a series of videos that discuss the price trends of the various solar cell construction methods. These videos are very technical and include costs of material components for processing, creation of the panels, and mounting in aluminum frames for handling. NREL calculates a solar panel factory has to be capable of producing a whopping minimum of one gigawatt worth of solar panels per year to be competitive in today’s market.

Of course, that big of a factory has large overhead expense which must be divided up and added to the cost of the final product. NREL figures there is a 7 percent loss of product due to breakage and poor processing of the silicon. Thus each panel costs 7 percent more than a panel coming from a factory with no losses. Thicker panels last longer, but have lower efficiencies.

Other costs of doing business such as overhead, profit, and disposal of defective product must be added on. Motorola Semiconductor learned long ago that going from 3-inch diameter silicon ingots to 4-inch lowered the cost of their products. The solar industry is at the 4-inch stage now and may be in the 6-inch product range by the time the solar panels need replacement.

This trend to thicker silicon may trigger a needed redesign of the panel system to match the voltages of the new panels to the inverter electronics. My point: The cost of the electronics in the inverters will not be dropping in price as time goes on.

NEXT WEEK: A look at environmental damage, and local heat warming

Related posts:

Gordon is a frequent contributor to The County Compass