After I left RCA in New Jersey, I was hired in 1987 as a product manager at Television Technology Corp. in Broomfield, Colorado. My product lines included AM and FM radio transmitters. Television Technology manufactured low power translators and transmitters. Translators receive either FM or TV signals over the air, change the TV channel or FM radio frequency to another one, amplify it on a the new output channel, and broadcast the signal in mountainous areas.

After I left RCA in New Jersey, I was hired in 1987 as a product manager at Television Technology Corp. in Broomfield, Colorado. My product lines included AM and FM radio transmitters. Television Technology manufactured low power translators and transmitters. Translators receive either FM or TV signals over the air, change the TV channel or FM radio frequency to another one, amplify it on a the new output channel, and broadcast the signal in mountainous areas.

Translators were the beginnings of cable TV as the cable companies received these signals off-air, changed the channel again and put them on a single cable to bring them into homes where off-air signals were not available or too weak to get a picture.

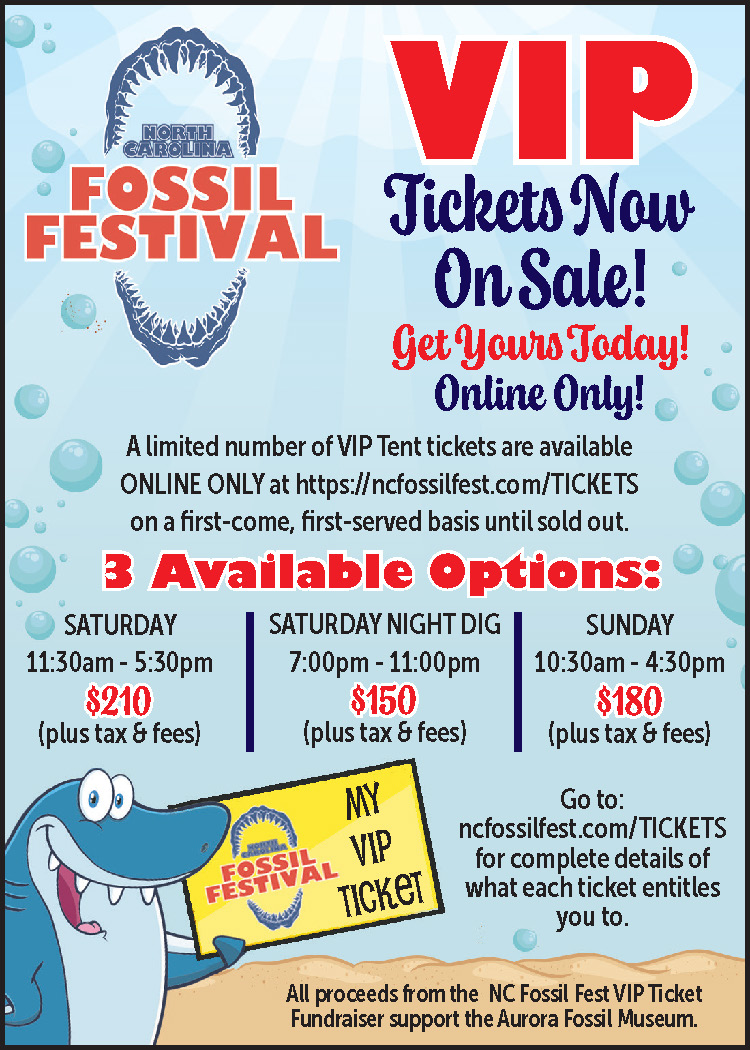

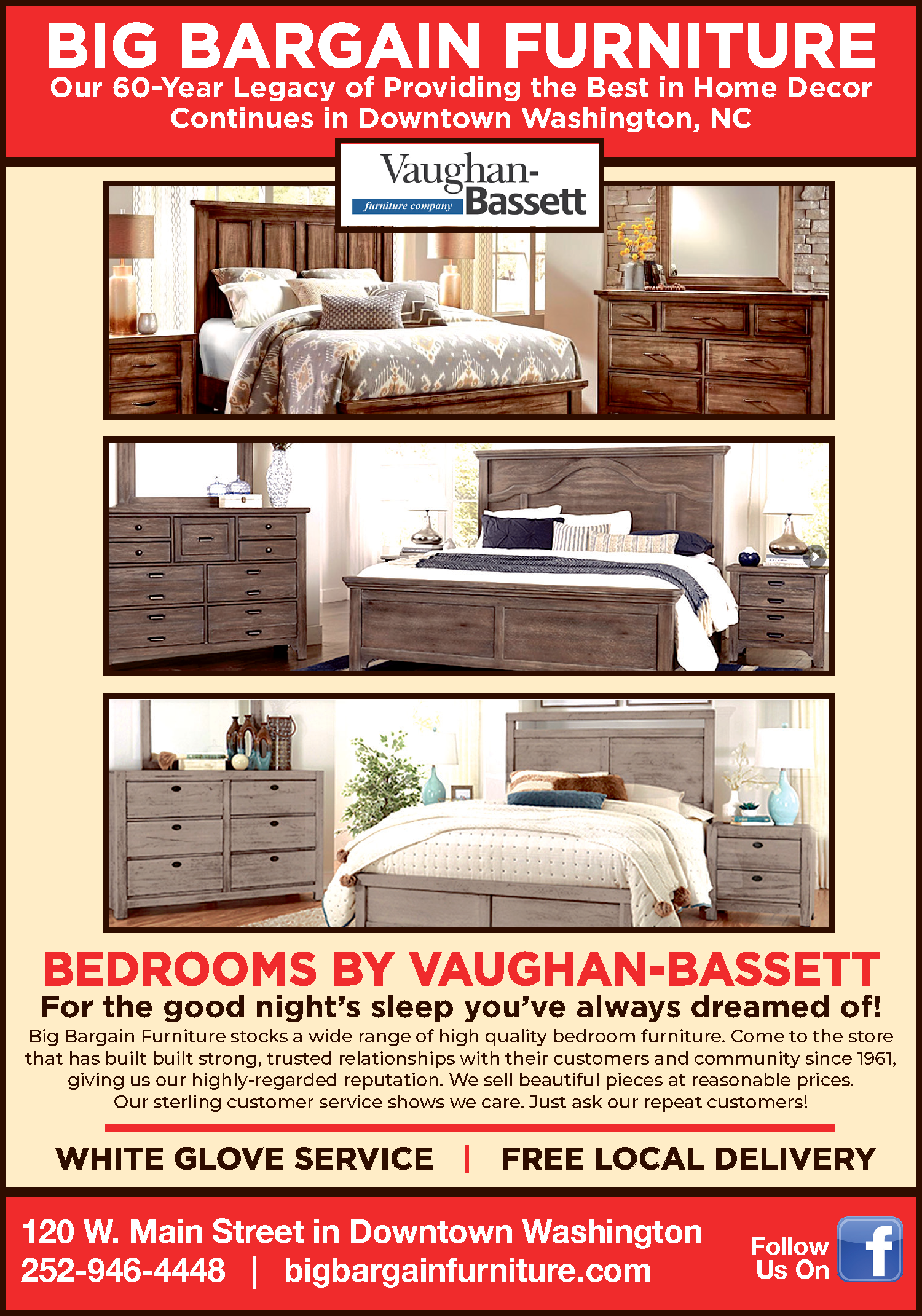

The Federal Communications Commission has technical standards to minimize interference among all stations. Three-pole filters allow only one channel’s signal to pass while removing spurious signals from the transmitter. The filters are made of copper-plated steel, which is then silver-plated for high electrical conductivity.

I liked to walk around the factory floor to see what was going on and learn what processes were used to create the products that I managed. The employees got used to my asking questions and answering theirs. Unbeknownst to me, I was using a management principal that was called “Management By Walking Around.” I don’t know who developed the principal, but Bill Hewlett and David Packard practiced it at the high tech company they founded (HP).

While walking around one day, I spoke to a lady from Thailand named Cam Lu, who made the three-pole TV channel filters for low power translators and transmitters. Her job was to clean the silver plating so it is really shiny, assemble the filters, and solder the components to the inside of the filters.

One day Cam Lu complained to me that she didn’t feel well. I asked her to take me through the three-pole filter assembly process. She said she took the pieces over to a work bench where she used Freon to clean the silver, then took them back to her work bench, where she used a propane torch to heat the places where she applied solder.

I surmised Cam Lu typically returned to her work station before the Freon had evaporated. The flame changed the Freon fumes into dangerous phosgene gas, which had been used by the Germans in World War I to kill enemy troops. I explained to Cam Lu that she must wait until all the Freon had evaporated before she applied the torch to the parts. I also explained the problem to her supervisor and asked her to be sure Cam Lu was OK and got lots of fresh air to clear her lungs.

By the time I walked back to my office, there was a message from the Manufacturing Vice President wanting me to come see him immediately. He went off on a rant, saying I was scaring the workers with my nonsense. I explained that the worker had no idea what the hazard was until I explained it to her.

Besides, I thought it was bad form to kill one of our best workers!

Meanwhile someone called OSHA, and they came to investigate. Later, the Manufacturing VP accused me of making the call to OSHA, but I had never done so.

OSHA found several issues and required Television Technology to generate material data sheets for all the chemicals used around the plant. After the report came in, the Manufacturing VP called me to his office and bragged that there was nothing said about the phosgene gas problem. Maybe I should have used a little more tact, but I told him that OSHA’s people were not the brightest bulbs in the box, so they weren’t able to find the problem. Shortly after that I called the Chief Chemist at Colorado’s natural gas supplier and related the situation. She said, “Oh MY GOD! Didn’t OSHA know about phosgene gas?” I replied, “I guess not.” I gave her phone number to the Manufacturing VP, indicating perhaps she would explain the problem better than I had. The VP never let on as to whether or not he called the chemist.

My point is this: Government seldom knows what’s really happening.

Gordon is a frequent contributor to The County Compass